Propane Gas Cylinder Production Lines

-

The following production lines can be customized on demand Step1 : Blanking & Body Forming Line Step2 : Welding, Heat Treatment and Hydrostatic Testing Line Step3 : Valve Guard Ring & Foot Ring Production Line Step4 : Valve Neck (Valve Boss or Neck Ring) Production Line Step5 : Surface…

The following production lines can be customized on demand

Step1 : Blanking & Body Forming Line

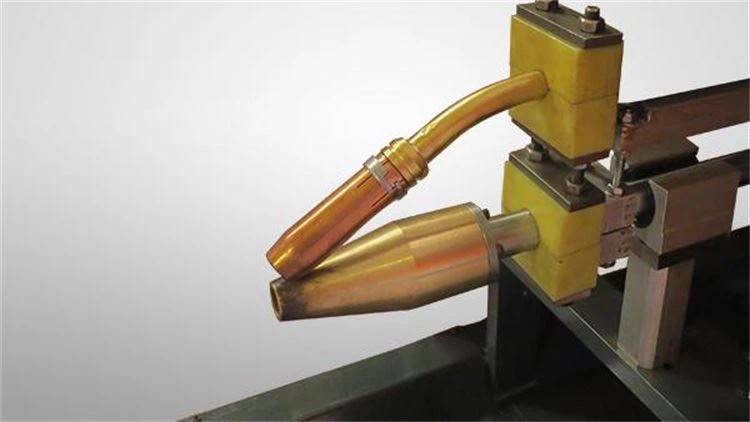

Step2 : Welding, Heat Treatment and Hydrostatic Testing Line

Step3 : Valve Guard Ring & Foot Ring Production Line

Step4 : Valve Neck (Valve Boss or Neck Ring) Production Line

Step5 : Surface Coating Line

Step6 : Finishing Line with Pneumatic Testing

1、Propane cylinder halves are formed in a cylinder body forming line. The hourly capacity required for a propane cylinder production plant determines the machine chosen in the body molding line. If the required cylinder production capacity is high, all body forming work can be done automatically according to the customer's requirements.

2、Machinery for the production of propane cylinders, trimming and necking in the same operation. According to customer requirements, the trimming die and the blanking die can be separated.

3、Propane gas cylinder guard rings (shrouds, collars) protect the valve from damage. The guard ring design may vary depending on the country of the customer. According to customer requirements, it can be a full circle or nearly half a circle. In addition, the number of nameplates at the connection of the cylinder to the grommet, the height of the nameplate and the text on the nameplate vary in each country's regulations.

4、The propane cylinder bottom ring protects the bottom of the propane cylinder from damage. Bottom ring design can be customized according to customer requirements.

5、Propane gas tanks are generally made of two half-cylinders welded around the center.

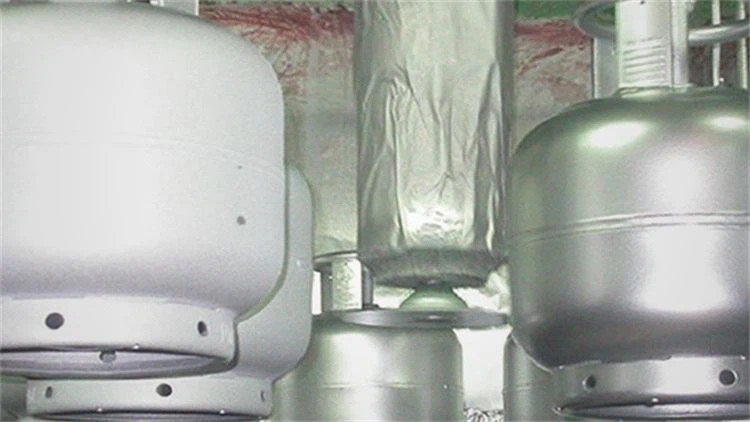

6、After the propane cylinder is produced, it must be tested to maintain a high production quality.

7、Propane gas cylinder heat treatment furnace with drive conveyor system for conveying cylinders. The cylinders are passed through the oven from inlet to outlet on a conveying system for proper heat treatment process including preheating, heating and cooling steps.

8、Propane cylinder shot blasting machines are used to automatically clean the surfaces of LPG cylinders by blasting grit material from the machine's turbine. LPG cylinders are shot blasted as they pass through the blast chamber on the machine base.

9、Metallization line will provide corrosion protection for propane gas Cylinders and it will increase lifetime of propane gas Cylinders.

10、Propane gas Cylinder Painting Line

11、Propane cylinder test line. Every newly produced propane cylinder is leak tested, hydrostatic and blaster tested on this inspection line. It is important to ensure that production quality is maintained at all stages of propane cylinder production and that the final product is good enough for public use.