Multifunctional Hydraulic Press

-

The Multifunctional hydraulic press is widely used. It is mainly suitable for the pressing process of metal materials, such as bending, flanging, extrusion forming, correction, pressing and so on.

Introduction

The Multifunctional hydraulic press is widely used. It is mainly suitable for the pressing process of metal materials, such as bending, flanging, extrusion forming, correction, pressing and so on.

Product Details

Features

1. Computer optimized layout design, gantry layout, complex, economical and applicable.

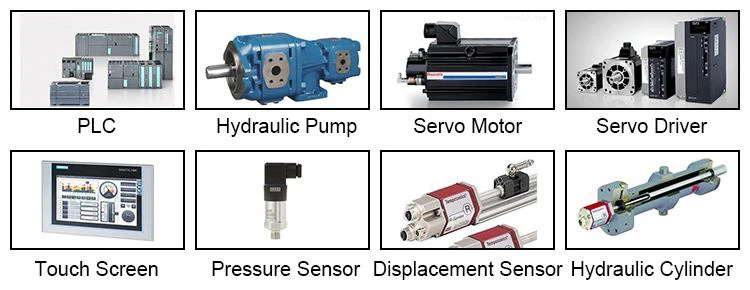

2. The hydraulic control adopts a cartridge valve integrated system, with adjustable pressure, fluctuating flow, reliable action, long application life, and increased continuous receiving paths and leakage points.

3. Automatic electrical control system, reliable.

4. Adopt button centralized control, with inching and semi-active control system

5. Through control and control assembly, it can complete two forming processes of fixed stroke and pressure, and has functions such as pressure holding delay

6.The duty pressure of the slider, the stroke range of no-load fast down and slow work advancement can all be adjusted according to process needs.

Operating System

1. Manipulation system: adjustment, manual, and semi-active three control systems.

2. restraint system: fixed pressure suppression and fixed range suppression.

3. The position of the slider stroke is inevitable through the stroke switch. The zero position in the master cylinder is at the top of the master cylinder. The change point is controlled by the same stroke switch. The stroke switch adopts a non-contact proximity switch. (Control precision <0.2mm)

4. The hydraulic pressure of the multi-function hydraulic machine is controlled by the ATOS proportional pressure regulating valve, and there is a pressure sensor to respond to the pressure flag. The pressure can be adjusted accurately and the tonnage of the press can be displayed on the man-machine interface. Suppress tonnage accuracy <1T.

Company Overview

Our products are suitable for stretching and Bending, flanging, cold extrusion, blanking and other processes are also suitable for calibration, pressing, pressing of powder products, abrasive products, and pressing of plastic products and insulating materials. It has passed CE and ISO9001 quality system certification.

FAQ

Q1: How can I get a quotation?

A1: Pls tell us the machine you need, including quantity, raw materials and other requirements.

Q2: After I buy the machine, what will you do if I don't know some of the function?

A2: We will show you how to use the machine perfectly. Technical support and the video is available.

Q3: What can I do if the machine troubled after I buy it?

A3: We provide completely after sales service, and our engineers are available to service machinery overseas.