Bearing Press

-

This Bearing press can be used for the interference fit of the engine rocker arm assembly insert and the rocker arm, the combination of the gasoline engine piston and piston pin, the interference fit of the bearing and the sleeve, and the press of the motor rotor and the rotating shaft.

Introduction

This Bearing press can be used for the interference fit of the engine rocker arm assembly insert and the rocker arm, the combination of the gasoline engine piston and piston pin, the interference fit of the bearing and the sleeve, and the press of the motor rotor and the rotating shaft. It is a high-performance, high-precision and high-efficiency press-fit testing equipment used in various interference assemblies such as the gas car industry and the motor industry.

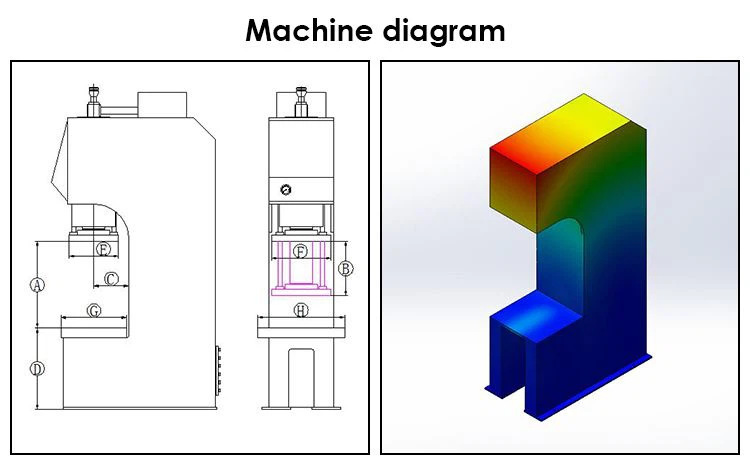

| Drawing notes | Type

Description |

Unit | HPCS-16T | HPCS-25T | HPCS-40T | HPCS-60T | HPCS-90T | HPCS-160T | HPCS-200T | HPCS-250T | HPCS-300T | |||||||||||

| Nominal force | KN | 160 | 250 | 400 | 600 | 900 | 1600 | 2000 | 2500 | 3000 | ||||||||||||

| Max. working pressure | Mpa | 15 | 18 | 24.5 | 21 | 25 | 24.5 | 24 | 24 | 25 | ||||||||||||

| Slider return force | KN | 28 | 55 | 55 | 64 | 87 | 126 | 126 | 274 | 306 | ||||||||||||

| Ejection force(Optional) | KN | 60 | 100 | 200 | 250 | 400 | 600 | 1000 | 1000 | 1600 | ||||||||||||

| Cushion force(Optional) | KN | 60 | 100 | 200 | 250 | 400 | 600 | 1000 | 1000 | 1600 | ||||||||||||

| Slider | Fast down speed | mm/s | (in/s) | 260 | 10.24 | 260 | 10.24 | 260 | 10.24 | 220 | 8.66 | 230 | 9.06 | 210 | 8.27 | 260 | 10.24 | 330 | 12.99 | 330 | 12.99 | |

| Working speed | mm/s | (in/s) | 30 | 1.18 | 23 | 0.91 | 20 | 0.79 | 18 | 0.71 | 18 | 0.71 | 16 | 0.63 | 15 | 0.59 | 17 | 0.67 | 13 | 0.51 | ||

| Return speed | mm/s | (in/s) | 170 | 6.69 | 160 | 6.30 | 150 | 5.91 | 175 | 6.89 | 200 | 7.87 | 230 | 9.06 | 250 | 9.84 | 150 | 5.91 | 140 | 5.51 | ||

| Ejection speed(Optional) | mm/s | (in/s) | 42 | 1.65 | 42 | 1.65 | 27 | 1.06 | 43 | 1.69 | 43 | 1.69 | 41 | 1.61 | 35 | 1.38 | 43 | 1.69 | 34 | 1.34 | ||

| Return speed of ejection | mm/s | (in/s) | 83 | 3.27 | 83 | 3.27 | 45 | 1.77 | 73 | 2.87 | 88 | 3.46 | 75 | 2.95 | 74 | 2.91 | 93 | 3.66 | 69 | 2.72 | ||

| Cushion speed (Optional) | mm/s | (in/s) | 42 | 1.65 | 42 | 1.65 | 27 | 1.06 | 43 | 1.69 | 43 | 1.69 | 41 | 1.61 | 35 | 1.38 | 43 | 1.69 | 34 | 1.34 | ||

| Return speed of cushion | mm/s | (in/s) | 83 | 3.27 | 83 | 3.27 | 45 | 1.77 | 73 | 2.87 | 88 | 3.46 | 75 | 2.95 | 74 | 2.91 | 93 | 3.66 | 69 | 2.72 | ||

| Motor power | KW | (HP) | 8 | 10.73 | 8 | 10.73 | 8 | 10.73 | 8 | 10.73 | 15 | 20.12 | 18.5 | 24.81 | 22 | 29.50 | 26 | 34.87 | 30 | 40.23 | ||

| A | Max. opening height | mm | (in) | 550 | 21.65 | 600 | 23.62 | 700 | 27.56 | 800 | 31.50 | 800 | 31.50 | 900 | 35.43 | 900 | 35.43 | 1000 | 39.37 | 1000 | 39.37 | |

| B | Slider stroke | mm | (in) | 350 | 13.78 | 350 | 13.78 | 400 | 15.75 | 500 | 19.69 | 500 | 19.69 | 500 | 19.69 | 500 | 19.69 | 500 | 19.69 | 500 | 19.69 | |

| Ejection stroke(Optional) | mm | (in) | 100 | 3.94 | 100 | 3.94 | 150 | 5.91 | 150 | 5.91 | 150 | 5.91 | 200 | 7.87 | 200 | 7.87 | 200 | 7.87 | 200 | 7.87 | ||

| Cushion stroke(Optional) | mm | (in) | 100 | 3.94 | 100 | 3.94 | 150 | 5.91 | 150 | 5.91 | 150 | 5.91 | 200 | 7.87 | 200 | 7.87 | 200 | 7.87 | 200 | 7.87 | ||

| F | Upper worktable | L.R. | mm | (in) | 450 | 17.72 | 500 | 19.69 | 500 | 19.69 | 550 | 21.65 | 550 | 21.65 | 800 | 31.50 | 800 | 31.50 | 1000 | 39.37 | 1000 | 39.37 |

| E | F.B. | mm | (in) | 320 | 12.60 | 350 | 13.78 | 350 | 13.78 | 450 | 17.72 | 450 | 17.72 | 500 | 19.69 | 500 | 19.69 | 600 | 23.62 | 600 | 23.62 | |

| C | Throat depth | mm | (in) | 280 | 11.02 | 280 | 11.02 | 300 | 11.81 | 320 | 12.60 | 320 | 12.60 | 340 | 13.39 | 360 | 14.17 | 380 | 14.96 | 450 | 17.72 | |

| H | Lower worktable | L.R. | mm | (in) | 550 | 21.65 | 550 | 21.65 | 700 | 27.56 | 800 | 31.50 | 800 | 31.50 | 1000 | 39.37 | 1000 | 39.37 | 1000 | 39.37 | 1000 | 39.37 |

| G | F.B. | mm | (in) | 480 | 18.90 | 480 | 18.90 | 550 | 21.65 | 600 | 23.62 | 600 | 23.62 | 600 | 23.62 | 600 | 23.62 | 700 | 27.56 | 700 | 27.56 | |

| Cushion size

(Optional) |

L.R. | mm | (in) | Customized | ||||||||||||||||||

| F.B. | mm | (in) | ||||||||||||||||||||

| D | Worktable height | mm | (in) | 900 | 35.43 | 900 | 35.43 | 900 | 35.43 | 900 | 35.43 | 900 | 35.43 | 1000 | 39.37 | 1000 | 39.37 | 1100 | 43.31 | 1100 | 43.31 | |

| Overall size | L.R. | mm | (in) | 1500 | 59.06 | 1500 | 59.06 | 1600 | 62.99 | 1600 | 62.99 | 1600 | 62.99 | 1800 | 70.87 | 1800 | 70.87 | 1900 | 74.80 | 1900 | 74.80 | |

| F.B. | mm | (in) | 1350 | 53.15 | 1350 | 53.15 | 1400 | 55.12 | 1550 | 61.02 | 1550 | 61.02 | 1650 | 64.96 | 1700 | 669.29 | 1850 | 72.83 | 2150 | 84.65 | ||

| Height | mm | (in) | 2700 | 106.30 | 2800 | 110.24 | 2950 | 116.14 | 3200 | 125.98 | 3200 | 125.98 | 3600 | 141.73 | 3700 | 145.67 | 4000 | 157.48 | 4000 | 157.48 | ||

| Weight | Kg | 2200 | 2200 | 3000 | 4000 | 4000 | 6500 | 8500 | 10000 | 12500 | ||||||||||||

Brief Overview of the Machine

This Bearing press adopts imported touch screen as data input and data display. The original imported American load cell is used as pressure acquisition signal. The system can calculate the pressure signal and displacement signal at a speed of 2000 times per second, and make various alarms and curves. Depict. The upper and lower limit curves of displacement and pressure can be preset to compare with the current press-fitting value, and any press-fitting position can be input to obtain the interference resistance generated by the position during the last press-fitting.

Features:

1. Energy efficient,electricity consumption than the average motor 30% -50%.

2. Low noise, the noise can be controlled at about 75 decibels.

3. Working position, speed, pressure can be infinitely adjusted.

4. Rapid response, high precision of pressure and repeat position.

5. High efficiency, with multiple internal protection, low failure rate.

6. 12 hours of continuous work without cooling oil temperature.

Why Choose Us ?

1.Quality Control through the whole Manufacturing process.

2.General Inspection on fixing before Packing.

3.Our products all passed ISO 9001.

4.Many other Designs for you to choose and we can Accept minimum order. Your interests can be fully Guaranteed.

Hot Tags: bearing press, China bearing press suppliers, manufacturers, factory, C Frame Press, Multi station Hydraulic Press, Cnc Hydraulic Press, C Type Hydraulic Press, Servo Hydraulic Press, Small Hydraulic Press