Sheet Stretch Forming Machine

-

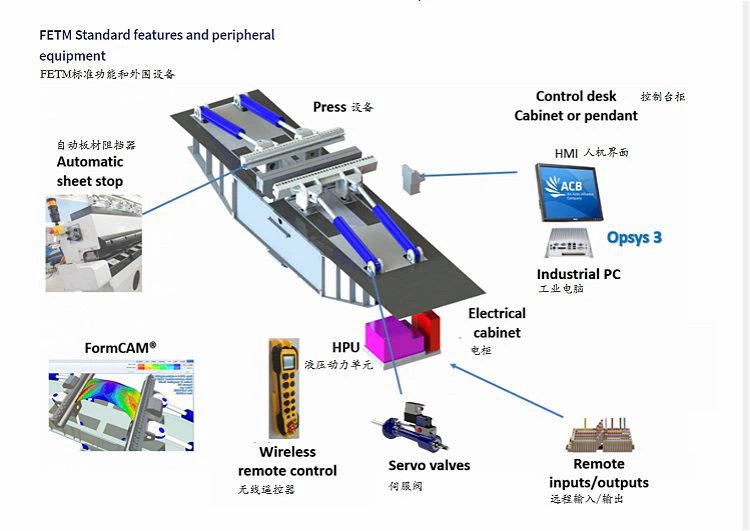

The servo sheet stretch forming machine adopts full hydraulic servo closed-loop control, which is easy to operate and has high production efficiency.

Introduction

The servo sheet stretch forming machine adopts full hydraulic servo closed-loop control, which is easy to operate and has high production efficiency.

Product Advantages

After the equipment’s stretch forming, the workpiece is perfectly curved, will not damage the surface of the workpiece, has high accuracy, good stability, and is not easy to deform. Hollow, complex cross-section profiles can be formed at one time. When the relative bending radius allows, the inner wall will not wrinkle and the cross-section will not be distorted (according to the drawing and bending process operation, using auxiliary materials to fill and stretch forming).

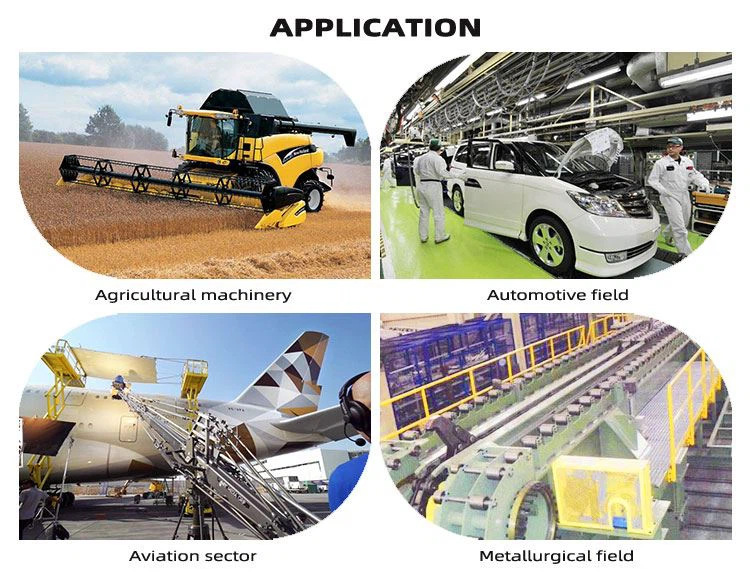

Application

The servo sheet stretch forming machine is mainly used in a variety of industries, such as aircraft skin, construction arc steel structure, bridge engineering, motor cars, roof bending beams, subway engineering, curtain walls, ceilings, display racks and other industries.

Company Overview

Our products are suitable for stretching and Bending, flanging, cold extrusion, blanking and other processes are also suitable for calibration, pressing, pressing of powder products, abrasive products, and pressing of plastic products and insulating materials. It has passed CE and ISO9001 quality system certification. The company has won a number of domestic patented products. It can develop and manufacture various special equipment and non-standard machine tools according to different production processes and material requirements of users. The products cover a wide range, reliable quality, and after-sales service The system is perfect.

Production Process

1.Raw Material

2.Whole Plate Grinding

3.Blanking

4.Welding

5.Fine Finishing

6.Polish

7.Upper Primer

8.Assemble

9.Spray Paint

10.Finished

Customer Questions

1. 24-hour Online service

Please feel free to contact us. Our sales team will provide you with 24 hours better pre-sale,

2.Warranty

All products have two years warranty.

3. Distributor

Prompt delivery and professional after-sales service are our priority, which makes us to be your reliable partner.

Hot Tags: sheet stretch forming machine, China sheet stretch forming machine suppliers, manufacturers, factory, Hot Forming Hydraulic Press, Stretcher For Aluminum, Aluminum Chips Cleaning And Compacting Line, Aircraft Parts Press Machine, Stretch Forming Machine, Soft Forming Servo Hydraulic Press