Aluminum Chips Cleaning and Compacting Line

-

Aluminum Chips Cleaning and Compacting Line is mainly applicable to the process of recycling aluminum chips.

Introduction

Aluminum Chips Cleaning and Compacting Line is mainly applicable to the process of recycling aluminum chips. Aluminum manufacturers produce a large amount of accumulated aluminum chips due to long-term processing of aluminum parts. Manufacturers often tend to clean, dry, pack the waste aluminium chips, and then recycle them. This greatly saves the company's costs, and at the same time makes a huge contribution to the recycling of non-renewable resources and environmental protection.

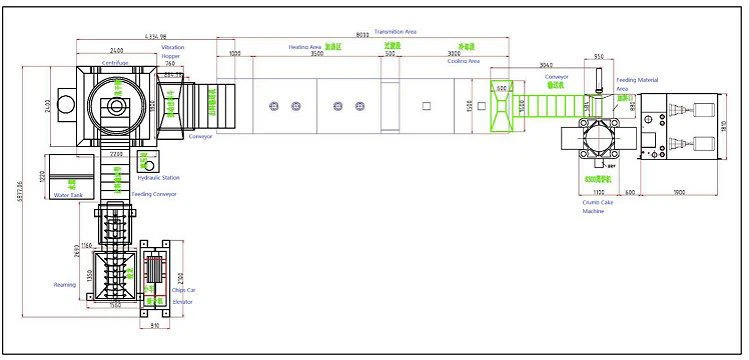

Product Parts

1.Elevator

Functions: Lift the chips car, and pour chips into the hopper. Equipped with safety protective nets.

2.Reaming& Hopper (Weldment)

Functions: Uniform output the material

3.Feeding Conveyor (Weldment)

Functions: Transport chips /Gather coolant

3.Centrifuge

Functions: Separating, washing and drying,Can simultaneously long and short feed material subjected to oil removal and without crushing

4.Cleaning Machine

Functions:Heating up water, washing away the dirt, cleaning the surface of aluminum chips.

5.Heating and Cooling Channel (Weldment)

Functions: Dry aluminum chips, reduce chips temperature.

6.Out-feed Conveyor

Functions: Transport materials to crumb cake machine

7.Crumb Cake Machine

Functions: Compress aluminum chips

8.Chiller

Functions: To reduce the oil temperature.

Company Overview

Wuxi Kelai NC Machine Tool Co., Ltd. is affiliated to Wuxi Klite Precision Hydraulic Machinery Factory. It is a professional, research and development, manufacturing and sales company that produces CNC servo hydraulic machine tools. The company's products have more than 100 varieties of various single-column hydraulic presses, four-column hydraulic presses, frame hydraulic presses, servo hydraulic presses, punching presses, etc., which are mainly used in the forming of aerospace parts and the hot pressing of automotive interior parts.

Our Advantages

We are an experienced factory

We provide a variety of hydraulic presses with different tonnages for you to choose

We can print your logo in our packaging

We can customize the color according to your needs

We can do OEM

Services

1. Product quality control and delivery time is strictly controlled;

2. Direct manufacturing factory offering competitive price;

3. All the inquiries will be replied within 12 hours;

4. OEM & ODM service are available;

5. Providing first-class after-sales services to the customers.

FAQ

1. Q: What is the quality of your products?

Answer: We have ISO, CE, etc. certificates so far.

2.Q: Can it be customized according to our needs, such as pasting our logo?

Answer: Of course, it can be customized as needed, or you can wear a logo.

3.Q: Are there any protective measures when packaging?

Answer: Cover with PE film, wrap with waterproof paper, wrap with wooden board, tie it tightly with steel tape, and fix it on the pallet.

Hot Tags: aluminum chips cleaning and compacting line, China aluminum chips cleaning and compacting line suppliers, manufacturers, factory, Servo Forming Hydraulic Press, Aircraft Parts Press Machine, Aluminum Chips Cleaning And Compacting Line, Stretch Forming Machine, Stretcher For Aluminum, Soft Forming Servo Hydraulic Press