Hydraulic Press Molding of Automotive Interior Parts

-

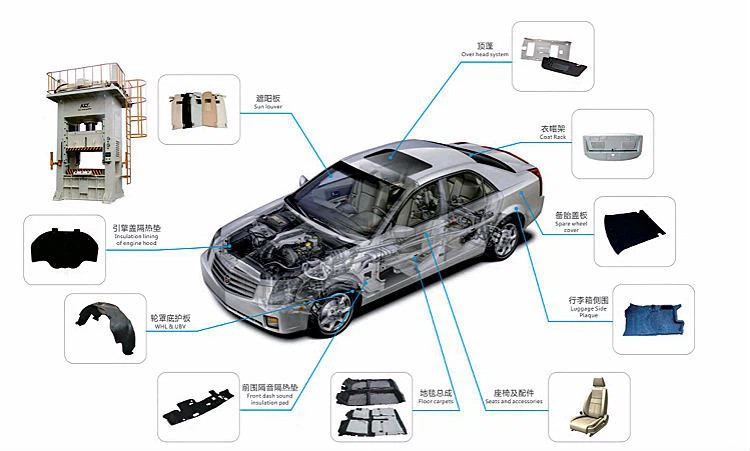

A new generation of hydraulic press molding of automotive interior parts with eight-sided frame guide structure. Applicable process, hot press forming of automotive interior parts.

Introduction

1. A new generation of hydraulic press molding of automotive interior parts with eight-sided frame guide structure. Applicable process, hot press forming of automotive interior parts.

2. Suitable for automobile headliners, luggage, seat back-to-back, coat racks, wheel guards, sun visors, hood insulation pads and other parts

3. The servo motor cooperates with the high-precision oil pump drive to control the pressure, speed and exhaust in sections.

4. PLC programming, touch screen display, control.

5. Precise control of displacement, speed and pressure sensor, arbitrary adjustment on industrial touch screen.

6. Provide remote network service, the machine automatically alarms to prompt failure and maintenance.

7. Suitable for trimming and compound molding of automotive interior parts

Features

1. High efficiency and energy saving, the power consumption is 30% -50% less energy than ordinary motors.

2. Low noise, the noise can be controlled at about 60 decibels.

3. The working position, speed and pressure can be adjusted steplessly.

4. Quick response, high pressure and position repeat accuracy.

5. High efficiency, multiple protections inside, and extremely low failure rate.

6. 12 hours of continuous work without cooling oil temperature.

7. Pipes and joints adopt SEA international standards to prevent pipeline oil leakage.

8. Adopt button centralized control, (fixed distance / constant pressure) two control methods, (adjustment / automatic) two operation methods.

9. European CE standard hydraulic system and electrical appliance safety IP54 level.

Application

Applicable to: The automotive interior industry is involved, which is dedicated to the hot press forming and trimming of various automotive interior products.

Hydroelectric Servo System Advantages

High efficiency and energy saving, reducing energy consumption, energy saving up to 80%

Flexible suppression, smooth operation, no shock and no vibration

Digital operation, digital setting of pressure displacement speed

Oil temperature control, intermittent work, no need for cooler

Noise control, equipment running noise is lower than 80 decibels

Floor Carpets

| Recommend capacity | 300 T | 400T | |

| Nominal force | 3000KN | 4000KN | |

| Opening | 1600mm | 1800mm | |

| Stroke | 1400mm | 1500mm | |

| Table size | L-R | 2400mm | 2400mm |

| F-B | 1800mm | 1800mm | |

| Slider speed | Fast down | 300mm/s | 300mm/s |

| Pressing | 10-30mm/s | 10-30mm/s | |

| Fast return | 150mm/s | 150mm/s | |

This press can be designed and made in accordance with customers’special requirements of processes.

Over Head Syetem

Technical parameter

| Recommend capacity | 200T | 300T | 500 T | |

| Nominal force | 2000KN | 3000KN | 5000KN | |

| Opening | 1400mm | 1600mm | 1700mm | |

| Stroke | 1200mm | 1400mm | 1500mm | |

| Table size | L-R | 3000mm | 3400mm | 4000mm |

| F-B | 2000mm | 2000mm | 2400mm | |

| Slider speed | Fast down | 300mm/s | 300mm/s | 300mm/s |

| Pressing | 10-30mm/s | 10-30mm/s | 10-20mm/s | |

| Fast return | 150mm/s | 150mm/s | 150mm/s | |

This press can be designed and made in accordance with customers’ special requirements of processes.

Experience and marketsOur factory was established in 2009 and has many years of experience in hydraulic press research and sales. Products are suitable for many fields, such as aerospace, automotive interior parts, ships, light industrial appliances, daily hardware, etc. The company has been affirmed by customers at home and abroad for its exquisite design, reasonable price, excellent quality and fast after-sales service and technical support. It sells well in more than 20 domestic provinces and cities, and its products are sold all over the world for long-term export. The United States, Europe, Japan, Southeast Asia, the Middle East, Russia and other countries and regions are well received by customers.

Our Service

1.Free on-site touring and introduction of our factory.

2.We provide validation for free.

3.We can guarantee on-time delivery of samples and goods.

4.Close follow-up of all orders by special person and keep customers informed timely.

5.All after-sale request will be responded in 24 hours.

FAQ

1.Q: How does your factory conduct quality control?

A: Quality is the top priority. From the beginning to the end of production, people have always attached great importance to quality control. Before packaging and shipping, each product will be carefully tested.

2.Q: What are your warranty terms?

A: We provide different warranty times for different products. Please contact us for detailed warranty terms.