H Type Hydraulic Press

-

This H type hydraulic press is used for forming of spectacle parts, lock parts, metal hardware, pressing assembly of electronic connectors, electric components and rotor & stator of motor etc.

Introduction

This H type hydraulic press is used for forming of spectacle parts, lock parts, metal hardware, pressing assembly of electronic connectors, electric components and rotor & stator of motor etc.

Wuxi Kelai NC Machine Tool CO.,Ltd is a subsidiary of Wuxi KLT Precision Hydraulic Machinery Factory. It is a professional manufacturer and saler of CNC servo hydraulic press machine with research and development ability. Kelai manufactures more than 100 types machines covering single-column, four-column, frame-type servo hydraulic press machines, which are mainly used in the form of aviation components and the thermoforming of automotive interior parts. Now it has achieved CE and ISO9001 certifications. The company owns a number of patents in China. It can develop and manufacture various special machines and non-standard machines on the basis of different production processes and different material requirements.Kelai has formed a perfect after-sales service system and supplies machines of good quality involving a wide range.

Features

1.A new generation of CNC hydraulic press, frame octagonal guide structure.

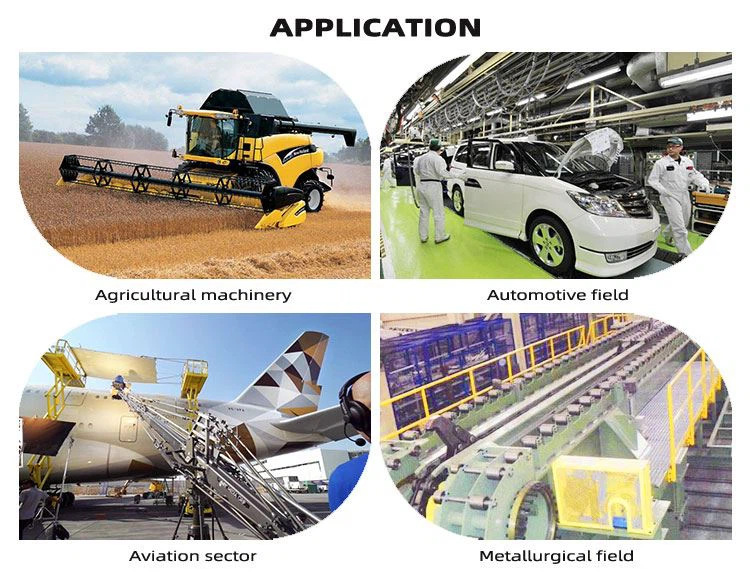

2.Applicable to medium-sized parts in industries such as automobiles, yachts, hardware, aviation, electronics, and electrical appliances.

3. Servo motor cooperates with high-precision oil pump to control pressure, speed and exhaust in sections.

4. PLC programming, touch screen display and control.

5. Displacement, speed, and pressure sensors are precisely controlled, and can be adjusted arbitrarily on the industrial touch screen.

6. Provide remote network service, and the machine will automatically alarm to indicate failure and maintenance.

Specification

| Description

Type |

Unit | HPHS

60T |

HPHS

100T |

HPHS

160T |

HPHS

200T |

HPHS

250T |

HPHS

300T |

HPHS

400T |

HPHS

500T |

HPHS

600T |

HPHS

800T |

HPHS

1000T |

HPHS

1500T |

| Cylinder pressure

(Optional) |

10T | 10T | 25T | 25T | 25T | 40T | 40T | 60T | 60T | 100T | 100T | 200T | |

| Heating plate size

(Optional) |

mm | 500x500 | 700x580 | 800x800 | 900x900 | 900x900 | 1300x1200 | 1400x1200 | 1700x1300 | 1800x1400 | 1800x1500 | 2000x1500 | 3000x2000 |

| Motor Power | KW | 15 | 15 | 18.5 | 22 | 22 | 29 | 28.3 | 29 | 40 | 40 | 45 | 45 |

| Fast down speed | mm/s | 60 | 70 | 80 | 80 | 80 | 120 | 150 | 150 | 300 | 300 | 350 | 350 |

| Speed of work | mm/s | 3-30 | 3-20 | 3-17 | 3-16 | 3-13 | 5-13 | 5-16 | 5-16 | 5-17 | 5-14 | 5-12 | 5-10 |

| Fast return speed | mm/s | 107 | 66 | 85 | 70 | 84 | 70 | 80 | 110 | 145 | 130 | 110 | 110 |

| Slow return speed | mm/s | 10-20 | 6-20 | 8-20 | 7-20 | 10-20 | 7-20 | 5-20 | 6-20 | 7-14 | 6-13 | 5-15 | 5-20 |

| Working pressere | Mpa | 25 | 25 | 25.5 | 25 | 25 | 25 | 25 | 25.5 | 25 | 25 | 25 | 25 |

| Maximum draft force | KN | 194 | 305 | 318 | 470 | 410 | 596 | 834 | 768 | 720 | 820 | 1200 | 1520 |

| Eject speed | mm/S | 16-54 | 7-67 | 8-43 | 8-43 | 8-43 | 10-54 | 10-54 | 6-65 | 6-65 | 7-55 | 7-55 | 5-40 |

| Return speed | mm/s | 79 | 98 | 63 | 63 | 63 | 110 | 110 | 120 | 120 | 70 | 70 | 94 |

| Top trip | mm | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 350 | 350 | 400 |

| Table size L.R | mm | 500 | 710 | 800 | 900 | 900 | 1300 | 1400 | 1700 | 1800 | 1800 | 2000 | 3000 |

| Table size F.B | mm | 500 | 580 | 800 | 900 | 900 | 1200 | 1200 | 1300 | 1400 | 1400 | 1500 | 2000 |

| Opening height | mm | 700 | 900 | 900 | 1000 | 1000 | 1200 | 1300 | 1200 | 1300 | 1300 | 1600 | 1600 |

| Cylinder stroke | mm | 500 | 500 | 500 | 700 | 700 | 800 | 800 | 900 | 900 | 900 | 1000 | 1000 |

| Weight | T | 4 | 5 | 7 | 8.5 | 8.5 | 17.5 | 19 | 25 | 40 | 45 | 70 | 120 |

Why choose us ?

1.Quality Control through the whole Manufacturing process.

2.General Inspection on fixing before Packing.

3.Our products all passed ISO 9001.

4.Many other Designs for you to choose and we can Accept minimum order. Your interests can be fully Guaranteed.

5.After you make order, we will Follow up the whole process and Update it to you. Collecting goods, Loading containers and Tracking goods transport information for you.

FAQ

1.Q: How does your factory conduct quality control?

Answer: Two-year quality warranty and lifetime technical support.

2. Q: What kind of machinery can you produce?

Answer: The automobile industry, metal stretching. Single-column hydraulic presses, four-column hydraulic presses, frame hydraulic presses, servo hydraulic presses, etc. for various purposes such as plastic products and powder molding.

Hot Tags: h type hydraulic press, China h type hydraulic press suppliers, manufacturers, factory, Frame Hydraulic Press, Briquetting Hydraulic Press, H Type Hydraulic Press, Automobile Beam Forming Hydraulic Press, Stamping And Stretching Hydraulic Press, Punching Hydraulic Press