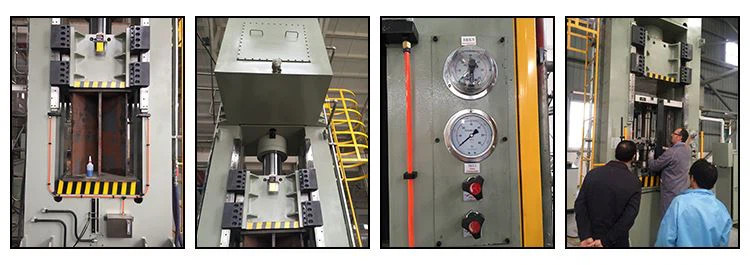

Cold Extrusion Molding Machine

-

Cold extrusion molding machine is mainly suitable for cold extrusion forming of metal materials;It is also suitable for embossing, forming, shallow drawing, forming, secondary forming and trimming of metal or non-metallic parts

Introduction

Cold extrusion molding machine is mainly suitable for cold extrusion forming of metal materials;It is also suitable for embossing, forming, shallow drawing, forming, secondary forming and trimming of metal or non-metallic parts;

Cold extrusion molding machine can also suppress typical products, including auto parts, watch case, watch strap, glasses frame and parts, photo frame, tableware, label, lock, hardware, etc.

Product Advantages

1.Two-speed, dual-motor, wide application range and high efficiency:

2.The frame and movable table have high precision, good rigidity and strong resistance to lateral force.

3.Especially suitable for high precision and asymmetrical products;

4.The movable workbench has high speed and high production efficiency;

5.The cylinder adopts integral forging and precision grinding, which has high reliability under high pressure.

6.The four columns are made of high-strength alloy steel, and the surface is plated with hard chromium, which has good wear resistance;

7.Adopt bottom-mounted cylinder, compact body

Application

Customized Solutions

KLT Customized Solutions are tailored to the requirements of individual customer. Our team of specialists, including hydraulic engineers, electrical engineers, testing engineers etc, can provide turnkey solutions that include hydraulic system design, electrical system design, producing lines supply, installation, testing and warranty. You don’t need to coordinate various suppliers, we are your one point of supplier.

You can count on KLT Customized solutions for your needs ranging from new product or market development to research, engineering and technical support. KLT will partner with you to assess your needs and provide a solution that will meet your market requirements and potentially increase your revenues and overall profitability.

Quality Control

1. Checking raw material before producing.

2. Checking one by one before the assebling

3. Checking one by one during the production

4. Have the random inspection before the delivery.

FAQ

1.Question: How does your factory conduct quality control?

Answer: Quality is the top priority. From the beginning to the end of production, people have always attached great importance to quality control. Before packaging and shipping, each product will be carefully tested.

2.Q: What are your warranty terms?

Answer: We provide different warranty times for different products. Please contact us for detailed warranty terms.